CNC (Computer Numerical Control) machines are advanced manufacturing tools that use computer software to control the movement and different operations such as cutting, drilling, and shaping of different materials.

CNC machines can be programmed to manufacture parts with high precision, accuracy, and consistency. This makes them ideal for the mass production of complex components. CNC Machines are widely used in various industries where high levels of precision and accuracy are required.

Some of the benefits of using CNC machines include:

- Increased productivity and efficiency

- Reduced labor costs

- Improved accuracy and consistency

- Ability to produce complex shapes and designs

- Faster turnaround times

- Reduced material waste

- Improved safety for operators.

Overall, CNC machines have revolutionized the manufacturing industry by making it possible to produce highly precise and complex parts at a much faster rate than traditional manufacturing methods.

So let's dive into the World of CNC with me

Different Types of CNC Machines

1- CNC Lathe:

|

1- An Operator Working on CNC Lathe |

CNC lathe is a type of machine tool that is used for shaping and machining cylindrical material. In lathe machine work piece is held in a device called a chuck and rotated. then a single point cutting tool removes the material from the workpiece bringing it to desired shape and size. All of these movements of cutter and workpiece are controlled by a computer programme, which ensures that the desired shape and dimensions are achieved with high accuracy and precision.

CNC lathes can be programmed for a variety of operations, including turning, facing, drilling, threading, and more. They are commonly used in the manufacturing industry to create complex parts for a variety of applications, such as automotive, aerospace, and medical devices.

One of the main advantages of using a CNC lathe is that it allows for faster and more efficient machining than traditional manual lathes. It also offers greater precision and repeatability, which is important for producing high-quality parts at scale. Overall, CNC lathes are an essential tool for modern manufacturing processes.

2- CNC Milling

|

| 2- A CNC Milling Machine |

CNC Milling machine uses a rotating cutting tool to remove material from the surface of the workpiece. The cutting tool is held in a spindle that can move along multiple axes to create complex shapes and features in the workpiece. The machine is controlled by a computer program that specifies the tool path and cutting parameters. CNC milling machines are used in a wide range of industries, from aerospace and automotive to electronics and medical device manufacturing. They are highly accurate and can produce complex shapes and features with a high degree of repeatability. CNC milling machines are essential tools for modern manufacturing, allowing for the efficient and precise production of parts and components.

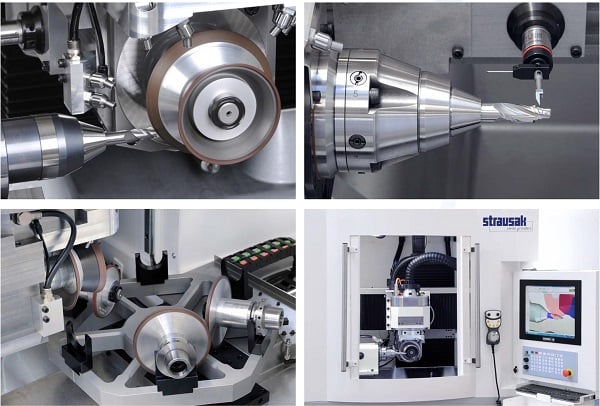

3- CNC Cutter Grinder

|

3- An Overview of CNC Cutter Grinder |

CNC cutter grinder machine is a specialized tool used in the manufacturing industry to sharpen and reshape cutting tools such as end mills, drills, and step drills. It uses computer numerical control (CNC) technology to automate the grinding process, improving accuracy and consistency while reducing operator error.

The machine typically consists of a rotating grinding wheel and a programmable control system that allows the user to input precise specifications for the tool's shape and size. The machine can grind tools to within a few microns of accuracy, allowing for precise and repeatable cuts. CNC cutter grinders are widely used in various industries, including aerospace, automotive, and medical device manufacturing, where precision cutting tools are essential for creating high-quality products.

4- CNC Plasma Cutter

|

| 4-A CNC Plasma Cutter in Action |

CNC plasma cutter is a type of computer-controlled machine that uses a high-velocity jet of ionized gas to cut through metal. The machine includes a plasma torch that generates an electrical arc between an electrode and the metal being cut. This arc ionizes the gas, which in turn heats up and melts the metal, allowing the plasma stream to cut through it with great precision. The CNC plasma cutter is capable of cutting through a wide range of metals, including steel, aluminum, and stainless steel, with thicknesses up to several inches. The machine is controlled by a computer that directs the plasma torch along the cutting path, allowing for intricate and precise cuts. The CNC plasma cutter is commonly used in industries such as metal fabrication, automotive repair, and construction.

5- CNC Wood Router

|

| 5- A CNC Wood Router |

CNC Wood Router is a computer-controlled cutting machine that uses a spinning router bit to cut and shape wood. It operates on three axes - X, Y, and Z - allowing it to create intricate 2D and 3D designs with high precision and accuracy. The machine receives its instructions from a computer-aided design (CAD) program, which is loaded into the machine's control panel. The CNC Wood Router can be used to produce a wide range of wood products, including furniture, cabinetry, musical instruments, and decorative items. Its high-speed cutting capabilities and automated operation make it an efficient and cost-effective tool for woodworkers and manufacturers alike. CNC Wood Routers come in a range of sizes and configurations, allowing users to choose the machine that best fits their specific needs and budget.

6- CNC Laser cutter

|

| 6- CNC Laser Cutter in Action |

CNC laser cutter is a machine that uses a high-powered laser beam to cut and engrave a wide range of materials such as metal, plastic, wood, and more. The laser beam is focused on the material, creating a high-energy density point that melts, vaporizes, or burns away the material. The machine is controlled by a computer, which ensures that the laser cuts or engraves the design with high precision and accuracy. CNC laser cutters can be used for a variety of applications, such as creating intricate designs, customizing products, and producing prototypes. They are highly efficient and produce clean cuts, minimizing waste and reducing production time. CNC laser cutters have become a popular choice in many industries due to their versatility, accuracy, and efficiency.

7- CNC Pipe Bending

CNC Pipe Bending machine is a specialized type of CNC machine used to bend metal pipes and tubes into specific shapes and angles. It operates using a computer-controlled system that controls the machine's movements, allowing for precise and accurate bending of pipes to meet the required specifications. The machine uses mandrels and clamps to hold the pipe in place and then applies pressure to bend the pipe into the desired shape. CNC Pipe Bending machines are commonly used in industries like automotive, aerospace, and construction, where pipes and tubes of various shapes and sizes are needed for different applications. They offer increased efficiency, accuracy, and repeatability in the bending process, resulting in reduced waste and cost savings for the manufacturer.

8- CNC EDM

|

| 8- An EDM |

CNC EDM (Electrical Discharge Machining) machine is a type of computer-controlled machine that uses electrical discharges to remove material from a workpiece. The machine consists of an electrode and a workpiece, both immersed in a dielectric fluid. An electrical discharge is generated between the electrode and the workpiece, which erodes the workpiece material, creating the desired shape. The electrode is moved along the workpiece's surface according to a computer program, which specifies the shape and depth of the cut. CNC EDM machines are commonly used for shaping and drilling hard materials, such as metals, ceramics, and composites. They offer high precision and accuracy, making them suitable for manufacturing complex and intricate parts. Additionally, CNC EDM machines are capable of producing a fine surface finish and can work with materials that are difficult or impossible to machine with conventional methods.

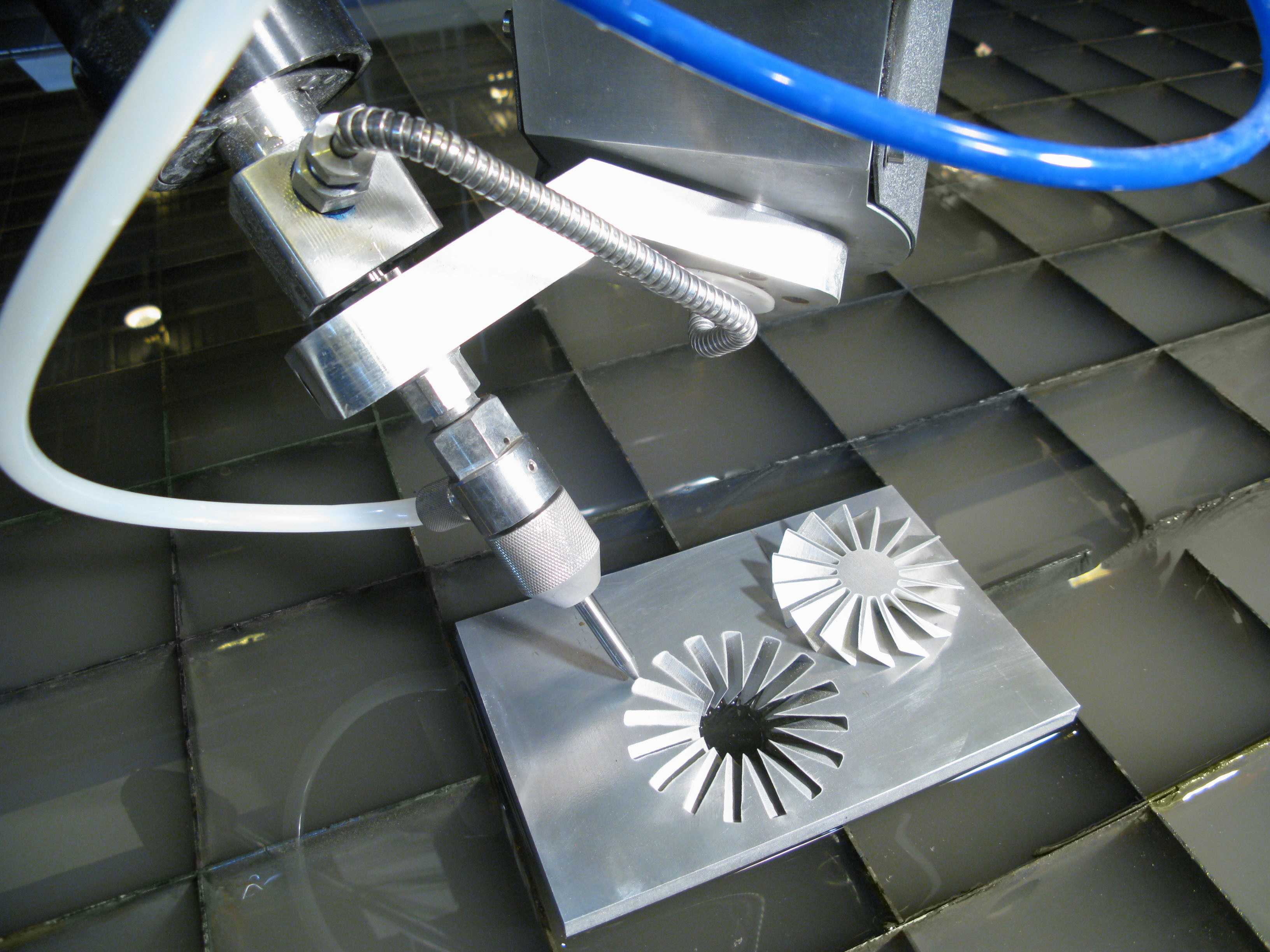

9- CNC Water jet

|

9- Water Jet Cutting Metal |

CNC water jet machine is a type of cutting tool that uses high-pressure water mixed with an abrasive material to cut through a variety of materials including metal, stone, and glass. The machine is controlled by a computer program, which directs the water jet to cut the material to the desired shape and size with high precision. This process is non-thermal and does not produce heat-affected zones, which makes it ideal for materials that are sensitive to heat, such as plastic and foam. The machine is capable of cutting materials up to 6 inches thick and can create intricate designs with high accuracy. CNC water jet machines are commonly used in industries such as aerospace, automotive, and architecture for cutting and shaping a wide range of materials.

No comments:

Post a Comment